Vision & Mission

Who are we?

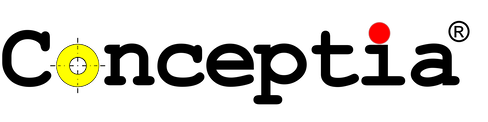

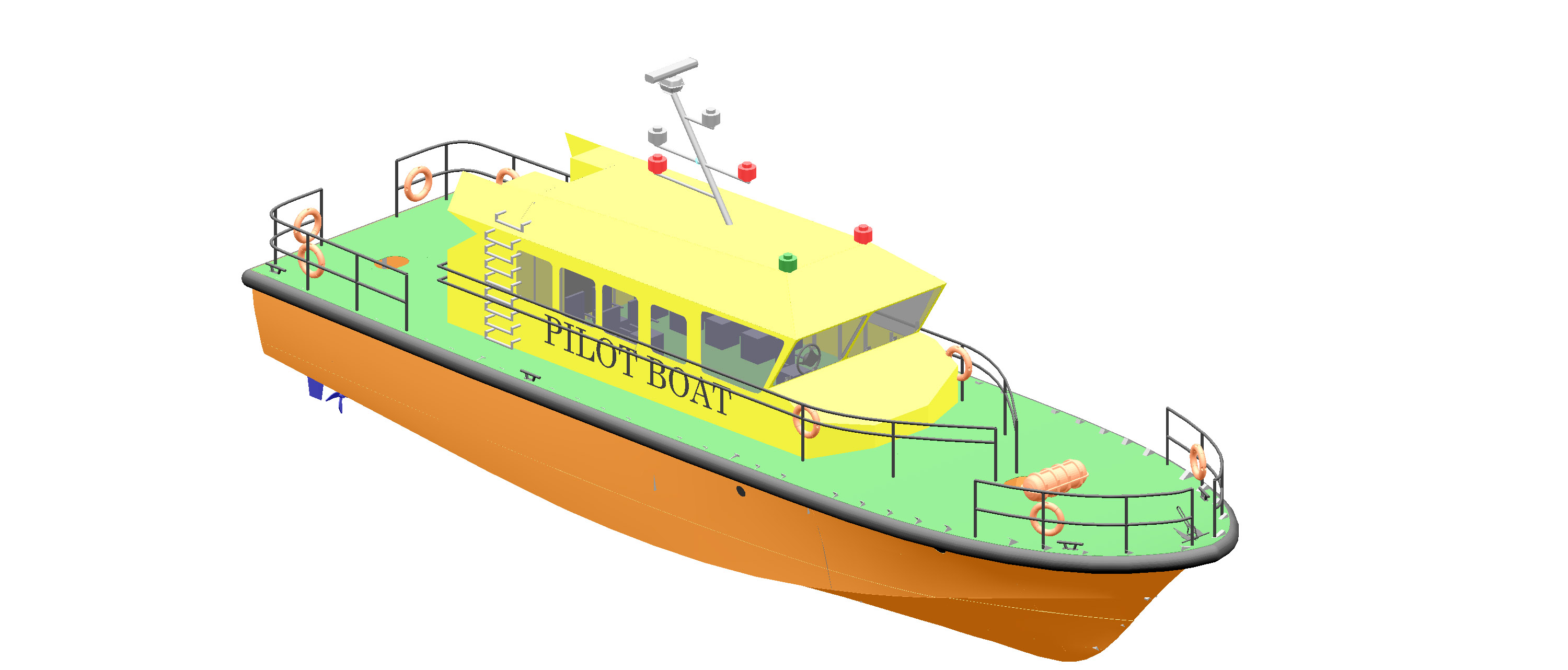

We are a large marine design and engineering solution provider serving the maritime industry across the globe; committed to offer innovative design, consultancy and engineering solutions. The zeal and dedication of our team of Naval Architects and Engineers is what defines us.

Since its inception in 2004, Conceptia has been known for its erudition, pre-eminence in quality and timely delivery. ISO 9001:2015 certification issued to the organization’s processes back a proven track record of quality and innovative solutions offered by us.

At Conceptia we emphasize on continually improving the processes of the company, constant learning through challenging projects in new domains, coupled with world class infrastructure. With our broad technical experience, constant improvement we have grown to serve in the following domains:

- Naval Architecture

- Marine Engineering

- Ship Design and Offshore Structures – Basic, Detail and Production Engineering

- Engineering Analysis

- Project Lifecycle Management

- Digital Publishing

- Staffing Solutions

- Product Sales – Engineering Enhancement Tools

- Training

Why Us?

With over 15 years of experience in extensive number of projects in the marine sector, we have nurtured ourselves to better serve our customers in the industry. We use the most advanced software tools, combined with the efficient workforce, helping us cater the most sophisticated needs of the industry.

Our highly skilled Project Management team is experienced and equipped to handle complex multi-disciplinary projects. Flexibility in our approach and process driven systems helps us adapt to new technology with ease.

We hire the best of the lot and make them better by constantly offering opportunities to learn, grow, develop and reward them for their contribution to enhance their capabilities, expertise and make their lives better at Conceptia and as an individual.

Download Brochures

From CEO’s Table

“Conceptia’s vision is to contribute to the national growth story in the field of Engineering. Conceptia contributes by way of providing engineering solutions to its global customer base and by skilling the youth of India to do so, thereby deploying Indian creative talent for global productivity enhancement and value addition.

I envisage a better quality of life for every Conceptian by excelling as a global company significantly impacting our customer’s productivity metrics. I also look forward to adding new areas of contribution in the field of engineering through innovative thought and action.”

Mr. Anildas N.T

CEO & Managing Director