Conceptia provides turnkey solution to Ship Owners & Operators by undertaking complete Ballast Water Management System Retrofit projects which includes Feasibility Study, System selection, BWMS Vendor co-ordination, Retrofit design (Basic and Detail design), Class and Statutory approval, Yard selection and co-ordination including complete project management.

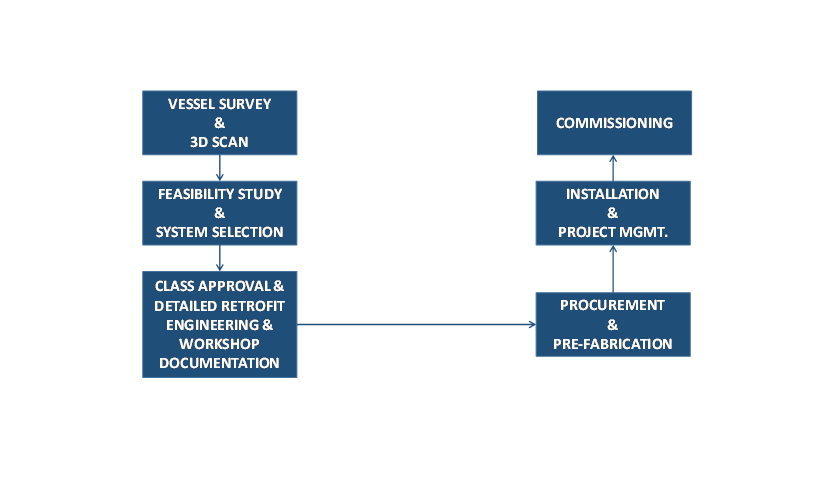

TYPICAL PROJECT FLOW

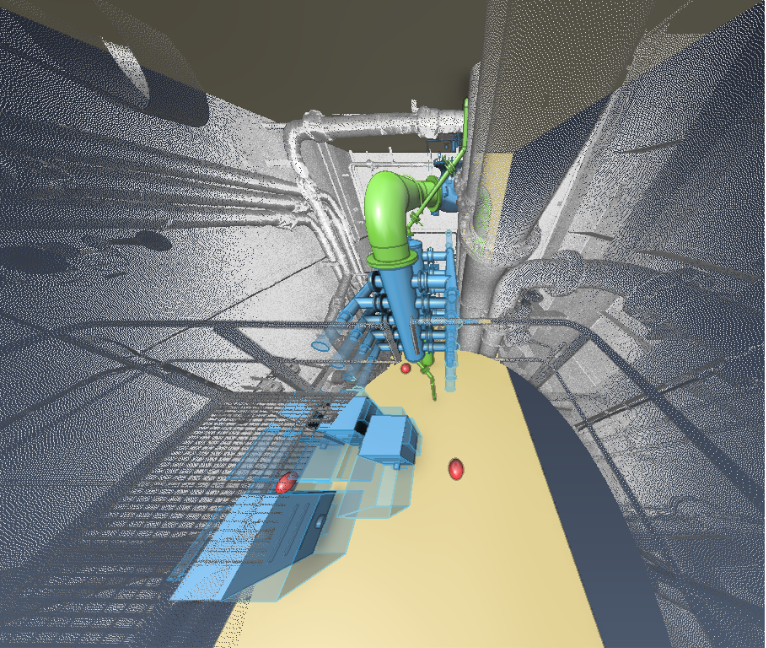

VESSEL SURVEY & 3D SCAN

- Field experts from Conceptia would be visiting the vessel onboard to do a complete visual survey.

- Identify and have a first cut idea if Conceptia has to initiate a feasibility study for retrofitting the vessel with BWMS. This survey can be done even when the vessel is in service and thereby avoiding any associated downtimes.

- If feasibility study to be initiated, 3D model generated out of 3D scanning techniques would be utilized in doing the feasibility study to install the BWMS system. Conceptia has a partner firm who is an expert in 3D scanning with wide experience in marine industry applications.

- From the survey if it is concluded that retrofit option is not feasible then Conceptia would check if containerized BWMS on deck is feasible/provide other feasible solutions accordingly to help client comply with statutory regulations.

- Onboard Survey is conducted with focus on following aspects

- Space

- Fresh Water & Compressed Air Demands

- Electrical Power Demand

- Sludge discharges

- Electrical connections

- Maintenance Space

- Foundation and Structural Integration

- Control System Integration

FEASIBLITY STUDY AND SYSTEM SELECTION

-

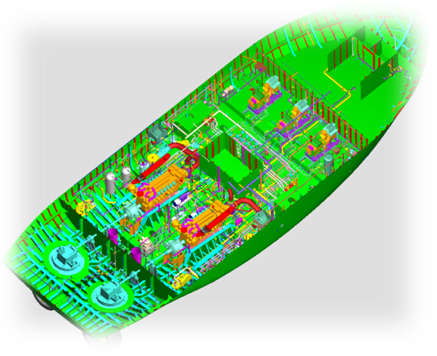

- Conceptia has experience in extensive number of projects in the areas of Retrofit, Naval Architecture, Detail design engineering and Production drawings.

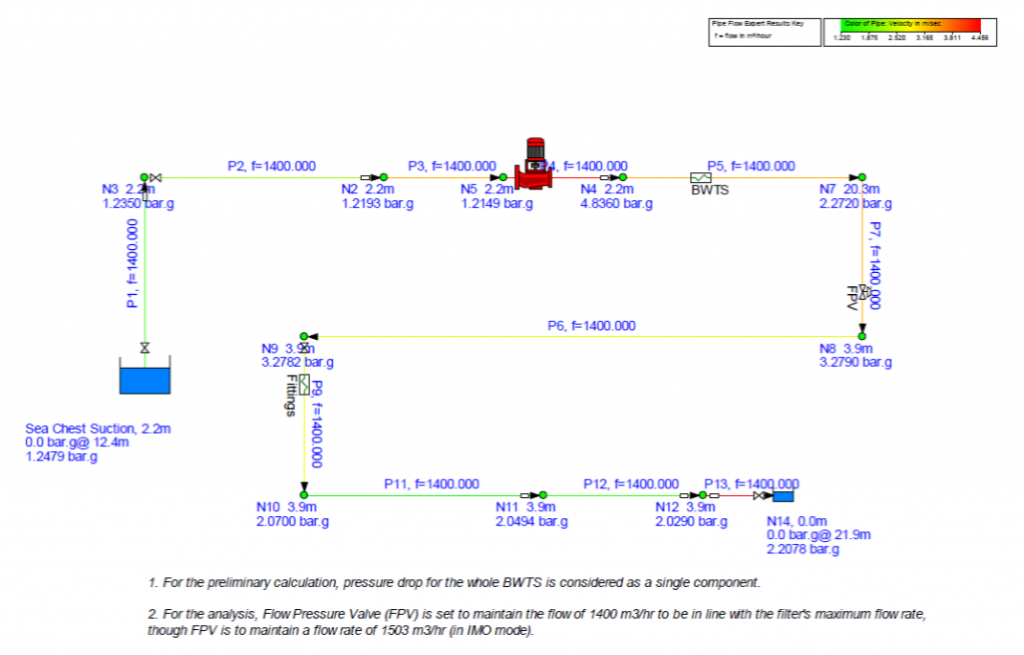

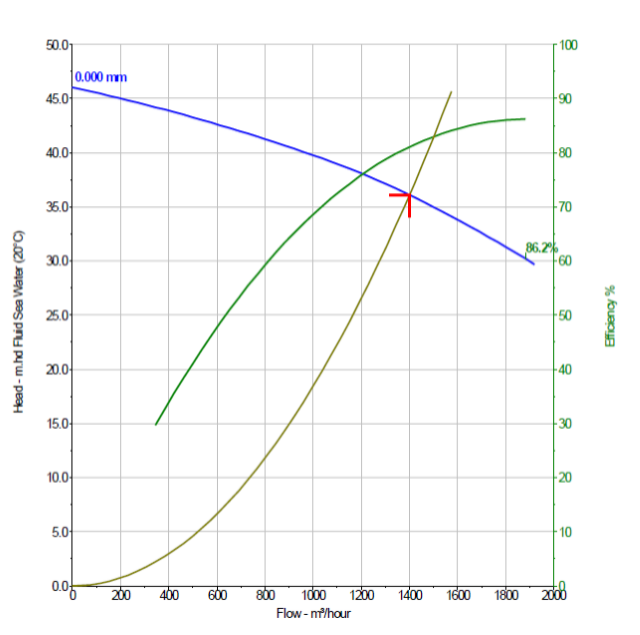

- Experience gained in the marine design field for the past 14 years would be utilized to do the feasibility study involved in the process of BWMS retrofit. The customer would be provided with the best possible solution to successfully integrate the BWMS system considering the following aspects.

-

-

- Statutory requirements

- Existing Ballast Operations

- Capacity of the BWMS to be installed

- Routing

- Space and Installation location

- Powering demands and its associated aspects such as Operational regimes and Auxiliary engines capacity

- System controls

- Fabrication and installation

-

- Conceptia has partnered with reputed and type approved BWMS system manufacturers, to combine our expertise and BWMS system expertise, to give expert solution in the area of BWMS projects to our customers.

DETAILED RETROFIT ENGINEERING

- As a part of the retrofit design process, Conceptia shall get BWM Plan approved by the regulatory bodies.

- Once the feasibility of retrofitting the vessel with BWMS is established and approved by the regulatory bodies then Conceptia will commence the detail design engineering to retrofit the vessel.

- Deliverables starting from schematics diagrams till spool drawings, penetration details, production drawings for structural modifications, Shipping In & Unshipping routes, Pre-fabrication and assembly details, etc. would be produced as a part of the detailed engineering.

- Conceptia shall submit the complete design documentation for the yard to schedule the production phases to align with vessel’s retrofit duration.

- Conceptia shall support the production yard in production, procurement of BWMS system, etc. till the system is commissioned and crew members are trained.

TYPICAL DELIVERABLES LIST FOR BWMS RETROFIT

PIPING

- Piping Diagram BWMS integrated with existing BWS

- BWMS Operation Manual

- Ballast Water Management Plan (D1/D1&D2/D2)

- Type Approval Certificate (TAC)

- Statement of acceptance of the BWTS (If Applicable)

- Hazard Analysis (If Applicable)

- Commissioning Procedure

ELECTRICAL

- Description of changes

- Updated electrical power single line diagram

- Making and breaking capacities of new circuit breakers

- Type Approval Certificate (TAC)

- Updated electric load balance

- Selectivity between new circuit breakers and upstream existing circuit breakers

- Emergency stop of new fans (if relevant)

- Updated EX documentation (As applicable)

FIRE SAFETY

- Structural fire safety integrity, detection, escape arrangement,etc. (If Applicable)

- Cargo Ship Safety Equipment Certificate (If Applicable)

CONTROL SYSTEMS

- Interphase description

- Environmental testing (I080) or data sheets of components (If Applicable)

STABILITY

- Lightship Calculation

- Inclining test report (If Applicable)

- New Trim and Stability booklet (If Applicable)

- An updated Watertight integrity plan (If Applicable)

- New Damage Stability calculations (If Applicable)

STRUCTURE

- Updated structural drawings (If Applicable)

- Foundation Drawings

PRODUCTION DRAWINGS

- Demolition Sequence

- Piping Production Drawings

- Electrical Production Drawings

- Structural Production Drawings

TYPICAL PROJECT TIMELINE

RETROFIT PHASES & DURATION

- Preparation, Onboard 3D Scanning & Survey – 4 Weeks

- Conceptia Retrofit Design (Including Feasibility Study) – 8 Weeks

- Class Approval Time – 4 Weeks

- Shipyard Preparation time on designer’s inputs – 3 Weeks

- Shipyard Retrofit Work – 6 Weeks

- Trial, Commissioning & Training – 2 Weeks